GUIDANCE FOR BUILDING OPERATIONS DURING THE COVID-19 PANDEMIC

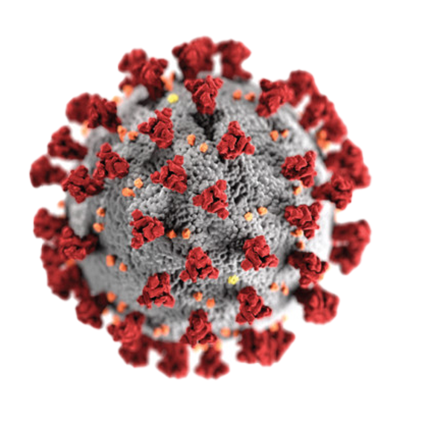

Coronavirus disease (COVID-19) is an infectious disease caused by a newly discovered coronavirus. The best way to prevent and slow down transmission is being well informed about the COVID-19 virus, the disease it causes and how it spreads. According to the WHO (World Health Organization), “The COVID-19 virus spreads primarily through droplets of saliva or discharge from the nose when an infected person coughs or sneezes”. Talking and breathing can also release droplets and particles. Droplets generally fall to the ground or other surfaces in about 1m, while particles, behave more like a gas and can travel through the air for longer distances, where they can transmit to people and also settle on surfaces. The virus can be picked up by hands that touch contaminated surfaces (called fomite transmission) or be re-entrained into the air when disturbed on surfaces. However, other mechanisms of virus dissemination are likely to be more significant: direct person to person contact indirect contact through inanimate objects like doorknobs through the hands to mucous membranes such as those in the nose, mouth and eyes droplets and possibly particles spread between people in close proximity Figure 1: COVID-19 transmission routes For this reason, basic principles of social distancing (1 to 2m), surface cleaning and disinfection, handwashing and other strategies of good hygiene are far more important than anything related to the HVAC system. This is a “game” of chance, and the fewer individuals who come in close contact with each other, the lower the possibility for the disease to be spread. Since symptoms do not become apparent for days or weeks, each of us must behave as though we are infected. Practical recommendations for building services operation: For those building which remain open or will re-open in the next few weeks, there are some non-HVAC actions is required to be made: Increase disinfection of frequently touched surfaces. Install more hand sanitation dispensers, assuming they can be procured. Shut down food preparation and warming areas, including the office pantry or coffee station. Close or post warning signs at water fountains in favor of bottle filling stations and sinks, or even better, encourage employees to bring their water from home. Once these basics are covered, a few actions related to HVAC systems are suggested, in case some spread of the virus can be affected, according to the guidance published by ASHRAE (American Society for Heating, Ventilation & Air-conditioning Engineers) and REHVA (The Federation of European Heating, Ventilation & Air-conditioning Association), There are some suggested precautions that can be taken into consideration during building operating hours. These precautions include: Increase air supply and exhaust ventilation: For those buildings which use mechanical ventilation system, increase the outdoor fresh air to be supplied (air change per hour) to the building would be helpful, if the ventilation is to reach 24/7 is much better and demand control ventilation (DCV) should be disabled, in addition lowering the population inside the building will cause in effective dilution ventilation per person. Also during spring time in which there is a limited requirement of cooling needs indoors, ventilation system can operate with increased rate of air supply during the whole building work periods without facing the problem of high energy consumption. Exhaust ventilation systems of toilets should always be kept in duty on 24/7, and under-pressure must be insured, especially to avoid the faecal-oral transmission. Use more window-driven natural ventilation: For those buildings that don’t have installed mechanical ventilation systems, the use of openable windows is recommended, even if this causes thermal discomfort. Open windows in toilets with passive stack or mechanical exhaust systems may cause contaminated airflow from the toilet to other rooms so, in these circumstances, it is recommended that toilet windows remain shut. If there is no adequate exhaust ventilation from toilets, and window airflow cannot be avoided, keep windows open in other spaces to achieve crossflows through buildings. Figure 2: Natural ventilation through building windows Safe use of heat-recovery devices: Heat-recovery devices may carry over the virus attached to particles from the exhaust airside to the supply airside via leaks. In rotary heat exchangers (including enthalpy wheels) particles deposit on the return airside of the heat exchanger surface, after which they might be re-suspended when the heat exchanger turns to the supply airside. Based on current evidence, it is recommended to turn rotary heat exchangers off temporarily during these circumstances. Its document goes on to state: if leaks are suspected in the heat-recovery sections, pressure adjustment or bypassing can be an option to avoid a situation where higher pressure on the extract side causes air leakages to the supply side. Transmission via heat-recovery devices is not an issue when a HVAC system is equipped with a run-around coil or other heat-recovery device that guarantees air separation between return and supply side. No Use of Recirculation: Virus particles in return ducts can also re-enter a building when centralized air handling units are equipped with recirculation sectors. It is highly recommended to avoid central recirculation. In case this leads to problems with cooling or heating capacity, this has to be accepted because it is more important to prevent contamination and protect public health than to guarantee thermal comfort. Air Filtration: Filtration in building heating, ventilation, and air conditioning (HVAC) systems can be a part of an overall risk mitigation approach but is not generally regarded as a solution by itself. We do know that low-efficiency filters (less than MERV 8 according to ASHRAE Standard 52.2 or less than ePM2.5 20% according to ISO 16890-1:2016) are very unlikely to make a difference. Improve central air filtration to the MERV-1311 or the highest compatible with the filter rack, and seal edges of the filter to limit bypass. Use of UV Lamps: A properly designed and maintained UV system, often in concert with filtration, humidity control, and airflow management, has been shown to reduce infections from other viruses. However, the details of the system are very important. Simply adding UV to an existing system without consideration of

GUIDANCE FOR BUILDING OPERATIONS DURING THE COVID-19 PANDEMIC Read More »